Shaoxing Samuel Advanced Materials Science and Technology Co. , Ltd.

About us

Company profile

Shaoxing Samagnet New Material Technology Co., LTD., founded in 2020, is a high-tech enterprise and scientific and technological innovation enterprise specializing in the research, development, production and sales of high-performance permanent magnet materials.

The main business scope includes Water treatment,Removal of copper ions;Nd-Fe-B material,devices,magnetic powder and alloy, permanent magnet motor manufacturing, processing; Magnetic powder for 3D printing (Nd-Fe-B, Mn-Bi), amorphous powder;Surface thermal spraying technology and services, such as wear and corrosion resistant layers .Self-management and agent all kinds of goods and technology import and export business (except country limit or prohibit the import and export of goods and technologies), amorphous soft magnetic materials, molded inductors, Fe-Si-B-C amorphous magnetic powder, etc., Sm-Co, Al-Ni-Co Mn-Bi magnets and magnetic disc material Tb-Dy-Fe, Ni-Mn,Gamagnetostrictive materials, new energy automobile motor, robot servo motor, electric aircraft motor design development and production, such as magnetic chuck magnetic application device research, development, production and sales.ew materials science and technology, electronic technology, mechanical and electrical technology in the field of technology development, technology consulting, technology services, technology transfer, electrical equipment, machinery and equipment manufacturing, processing (limited branch operation) above, electronic processing (limited branch operation), electrical and mechanical equipment and accessories, machinery equipment and accessories, electronic products wholesale, retail, etc.

The enterprise culture

Corporate mission: customer first, clean the world, magnetic future.

Mission statement: Continue to create value for customers, use permanent magnet materials to promote efficient power and green energy, innovation-driven, leading the future.

Corporate vision: to be the leader of permanent magnet material innovation

Vision Interpretation: Shaoxing Samuel will be built into a "global center of r&d, production and marketing of high-performance rare earth permanent magnets".

Corporate values: safety, struggle, innovation, integrity, responsibility

Interpretation of values: Safety is our primary core value. First of all, we must ensure that our employees are in a safe, healthy and environmentally friendly working environment. We have to work hard to make sure we get the job done; We should keep innovating for customers in our work; We must ensure the integrity of employees, partners; We should take responsibility for our society.

Corporate Research Team

It has four overseas experts, including two professors. The main researchers are Chinese Americans, who have been responsible for technology development of companies such as Magnetar, General Motors and Arnold & Co.

Preparation technology and advantages

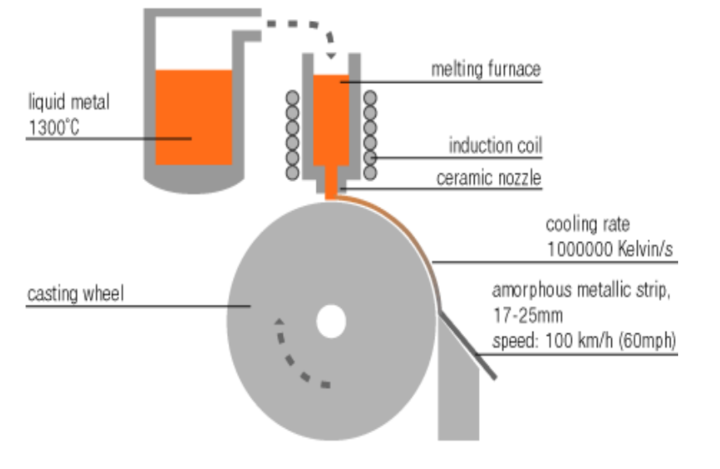

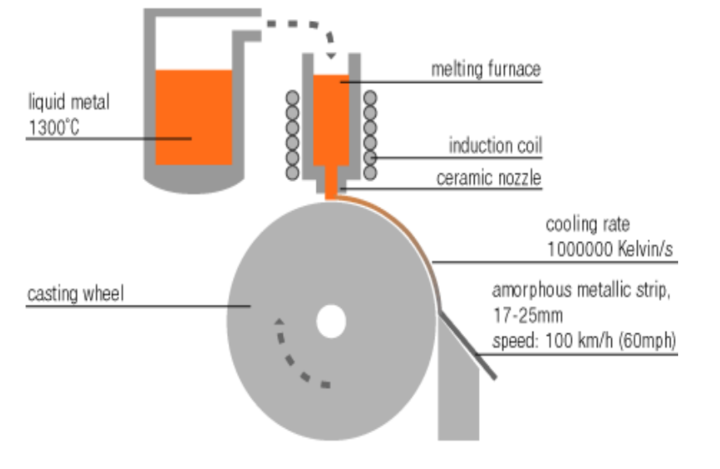

Advanced fast solidification spray tape technology

Advanced scale production technology

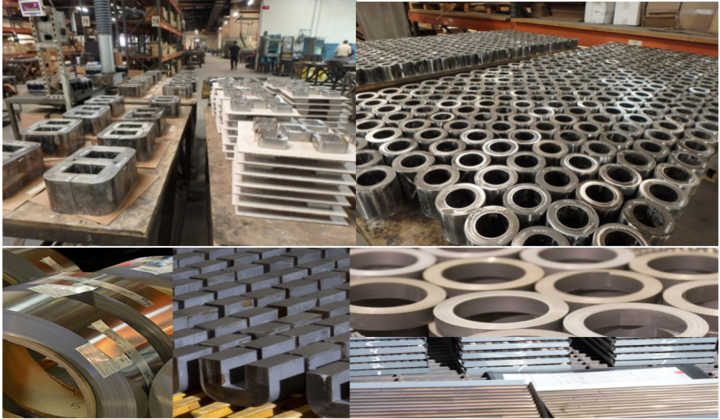

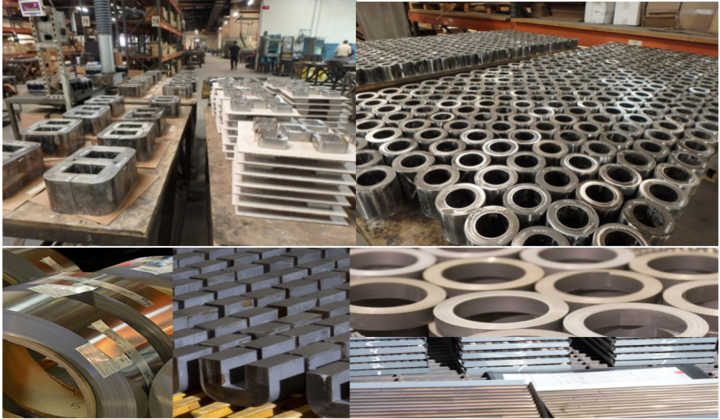

Advanced scale production technology Advanced cutting and annealing technology

Advanced cutting and annealing technology•The wound core can be manufactured by multiple cutting of various alloys (such as silicon steel, amorphous and ultra-low loss nanocrystals).

• World leading cutting and annealing processes.

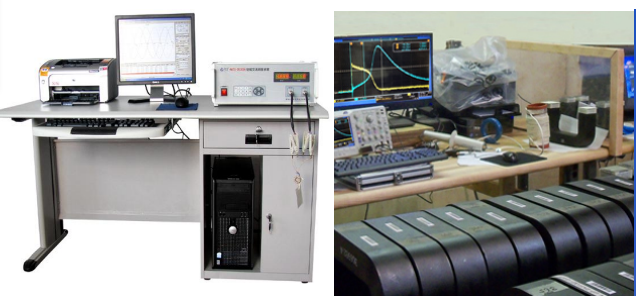

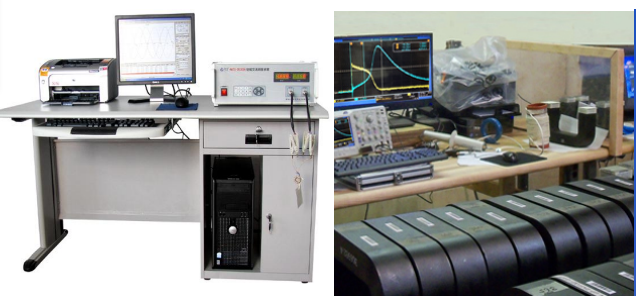

International docking magnetic inspection system

International docking magnetic inspection system Advanced quality management

Advanced quality managementLeadership in the magnetic industry is based on quality, consistency and flexibilityOn, can be adapted to any custom requirements around the magnetic tape core.

• Capable of manufacturing and fully testing iron cores from 1 ounce (28.35 g) to 1.8 tons.

• State-of-the-art testing LABS. Quality control equipment is equipped with a complete test system and automatic defective elimination line. Can provide DC roll drop, core lossAnd magnetic current test, three-phase test, CCFR and BH loop test, ring piece Matching, hot chamber test and other tests.

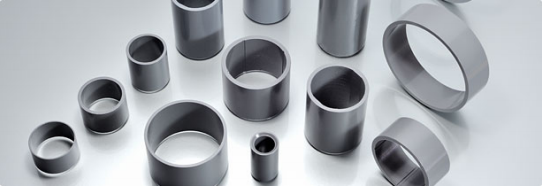

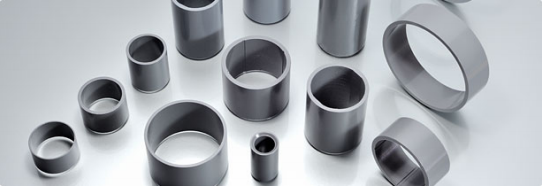

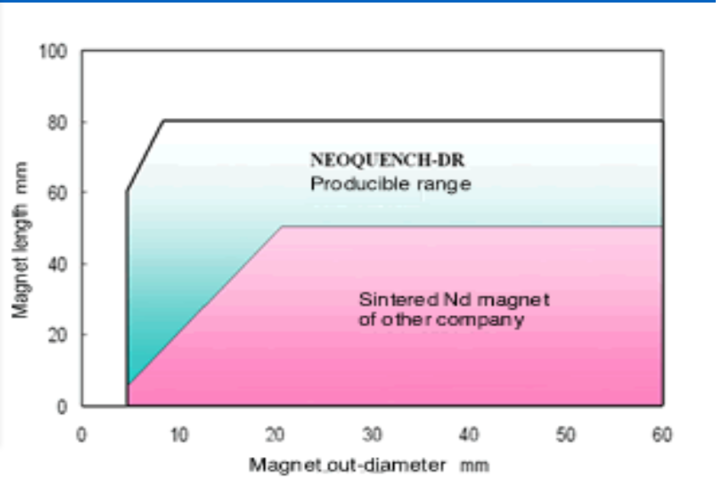

Hot pressed NdFeb advantage1.The permanent magnet motor is better than the tile

Hot pressed NdFeb advantage1.The permanent magnet motor is better than the tile• Multi-pole ring for permanent magnet motor, one ring for more watts, simple assembly, low assembly cost

• A ring of more than one watt, rotor external dimension accuracy is high, low torque

• A ring of daidowatt, high magnetic uniformity

• Thermal-extrusion radiation-oriented ring has a variety of magnetization options, and oblique charging multipole makes the motor more stable

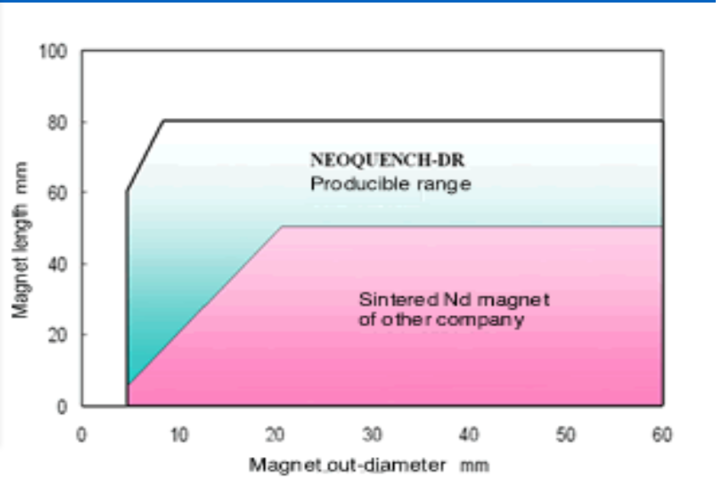

The magnetism of sintered radial ring is lower than that of heat extrusion radial ring due to cracking restriction

The heat extrusion radially converged ring, sintering multipolar ring, bonding multipolar ring and hot pressing non-oriented ring were all good

• Hot extrusion radially convergent ring has low Dy content, high yield, wide size range, high polar magnetic flux density and corrosion resistance

Good corrosion resistance

• Low Dy content, high yield, wide size range and good corrosion resistance of heat extrusion radial sintering multipole rings in sequential sintering process

• The magnetic flux height of bonded multipolar rings and hot-pressed non-oriented rings is higher than that of bonded multipolar rings

The hot extrusion convergent ring and sinter convergent ring market grow rapidly

The thermal extrusion radial ring process line is also suitable for the production of dY-SH block magnets and HV/EV drive electricity for axial oriented offshore corrosion-resistant wind power

The machine USES less DY-EH block magnet, and isotropic hot pressing block 17MGOe magnet, and hot extrusion radiating ring edge Angle

The waste material can be broken into bonding magnets and sold as anisotropic powder

2.The heat - squeezed radial ring is higher than the sintered radial ring

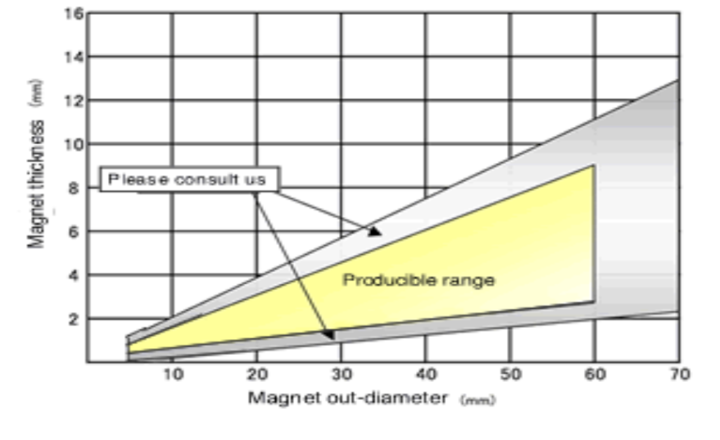

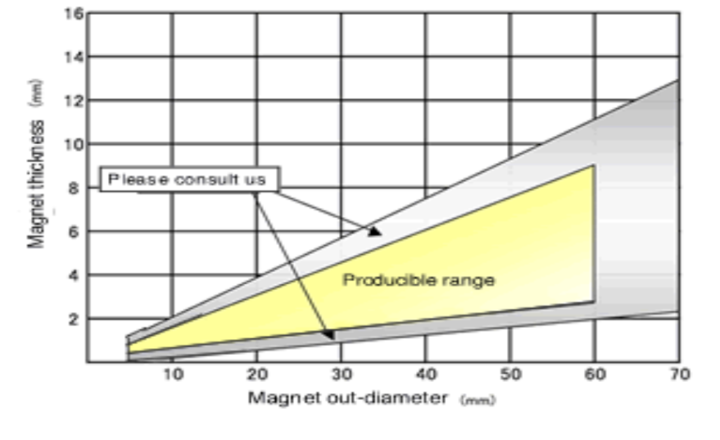

3.The heat squeezed radial ring is thinner than the sintered radial ring

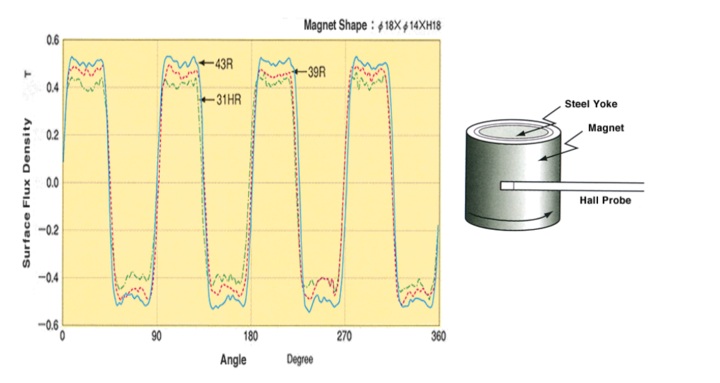

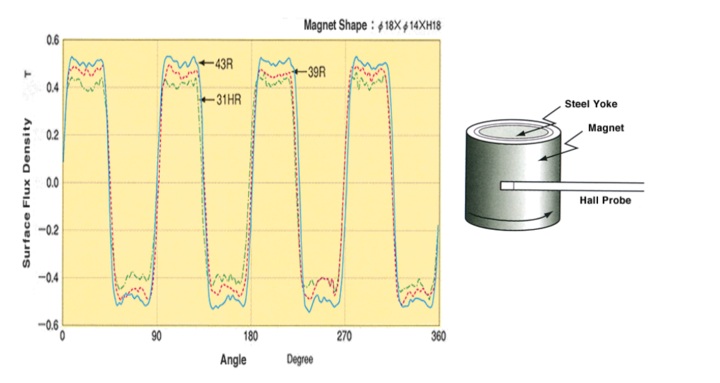

4.For example, the magnetic flux density of radiation-oriented ring multipole magnetized surface in hot extrusion,Magnetic flux ratio is higher than sintering

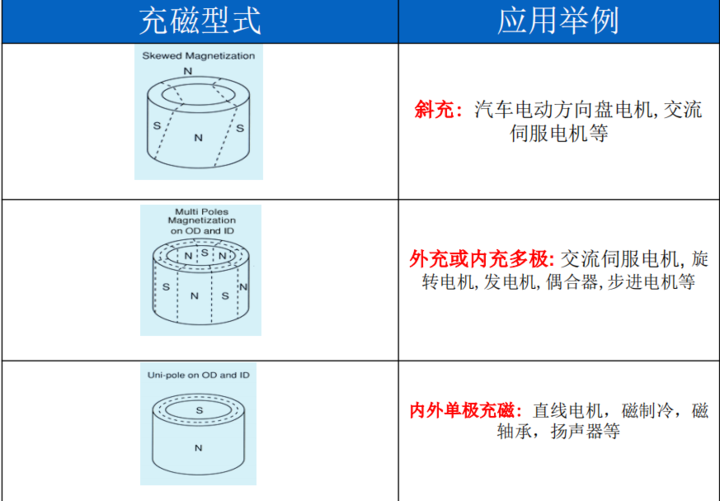

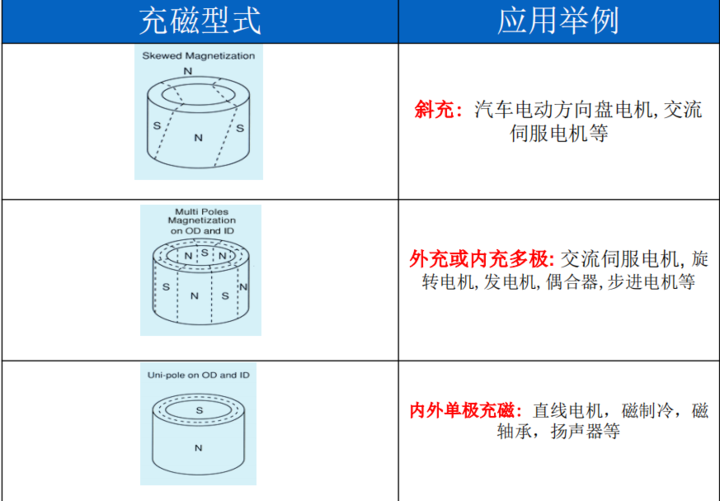

5.Examples of the types and applications of hot extrusion radiation-oriented ring magnetization

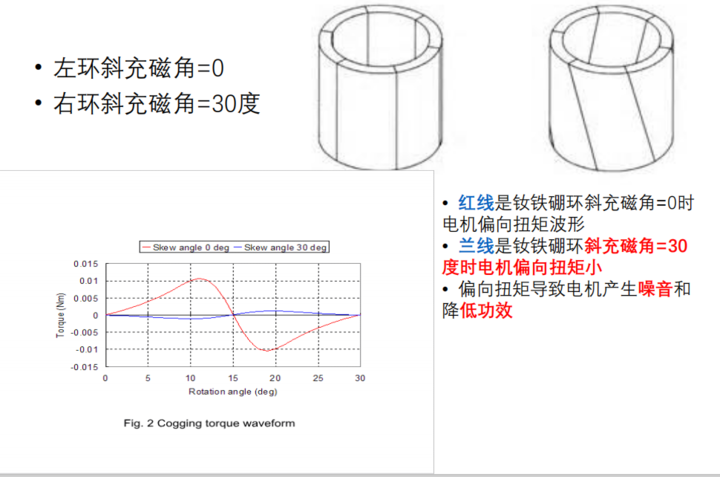

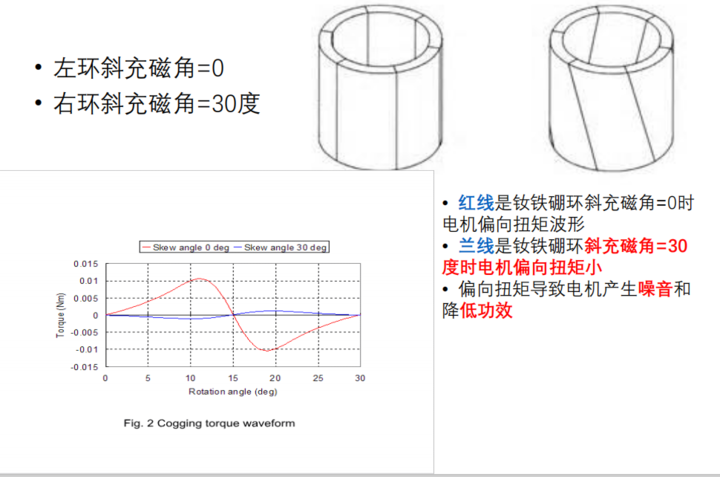

6.Diagram of magnetic poles for thermal extrusion ring with 15 degree oblique, 8 and 6 internal charges

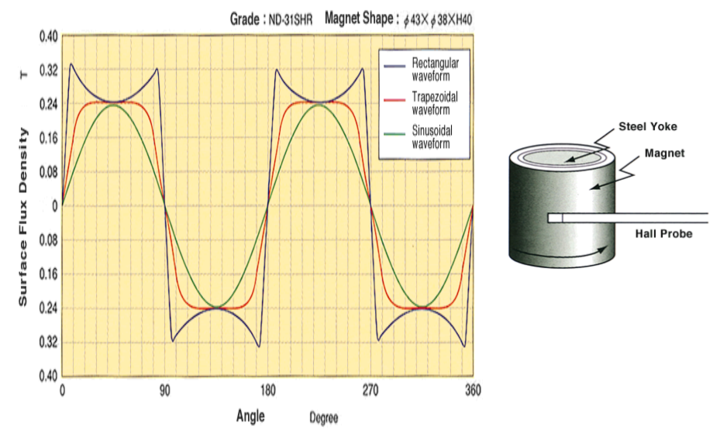

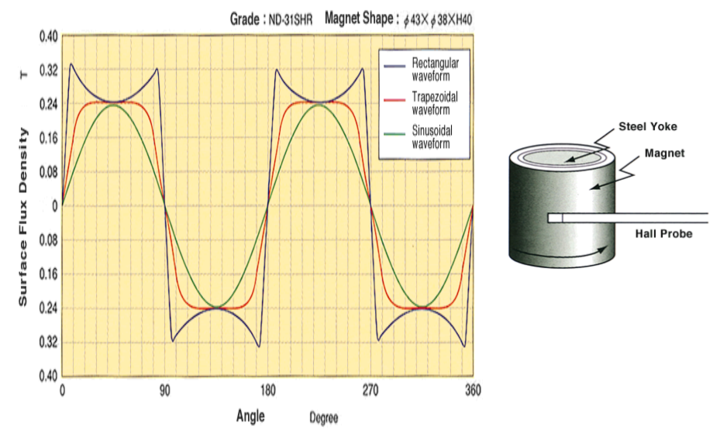

7.Hot extrusion radiation-oriented ring magnetization waveform: Blue - square wave, red - trapezoidal wave, green - positive black wave

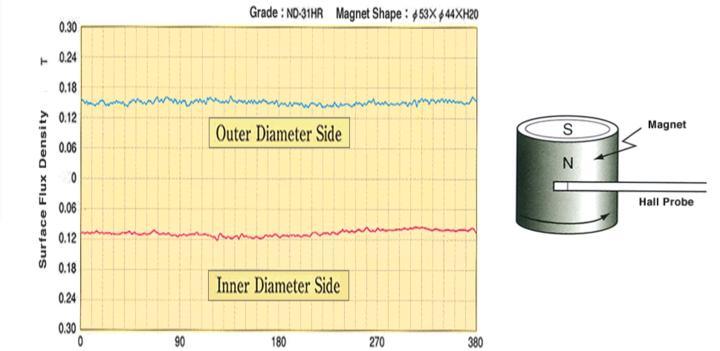

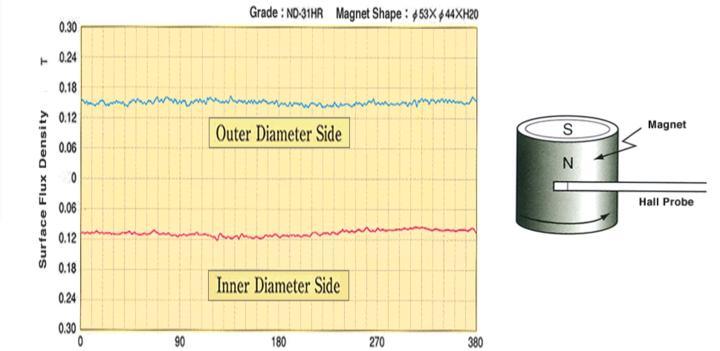

8.An example of magnetic flux density on the magnetized surface of a radiation-oriented ring is given

9.The advantages of inclined magnetization

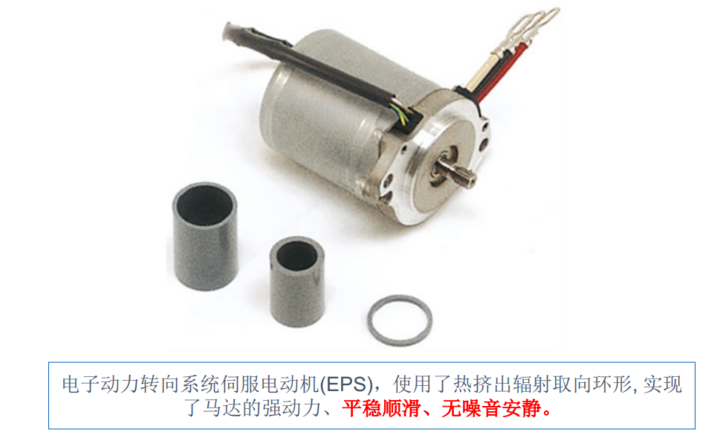

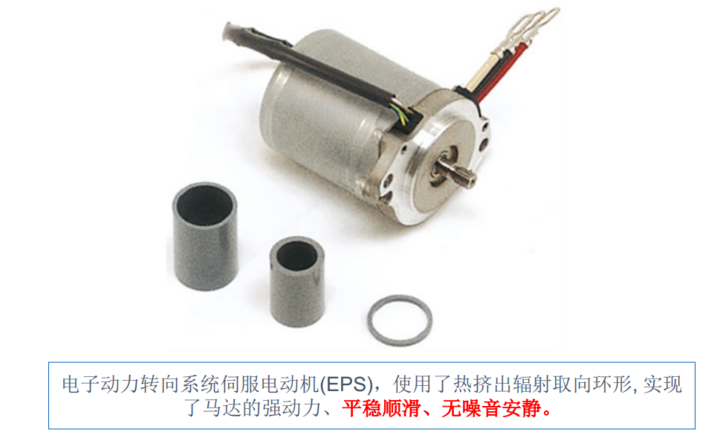

One of the typical applications of hot extrusion radiation-oriented rings: motors for automotive electronic power steering devicesTypical application of hot extrusion radiation-oriented ring ii: automobile motor

One of the typical applications of hot extrusion radiation-oriented rings: motors for automotive electronic power steering devicesTypical application of hot extrusion radiation-oriented ring ii: automobile motorA device used for basic functions such as driving, turning and parking.

• Such as automobile electric reversing motor, automobile anti-lock braking system, automobile electric braking motor and automobile automatic shift gear, etc.

• There are reports that the hot extrusion ring market will reach 7,400 tons annually due to increased demand from the auto industry.

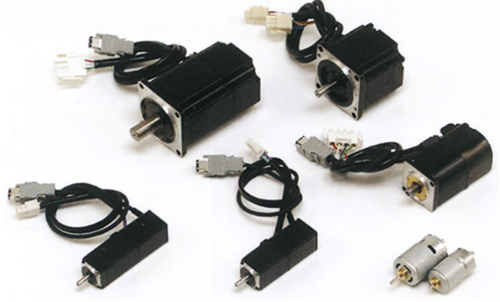

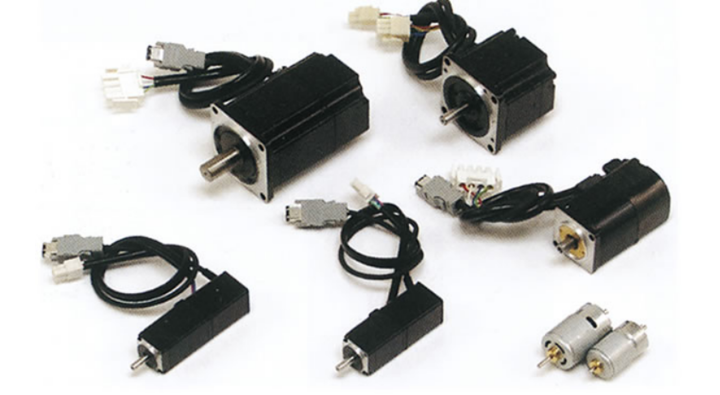

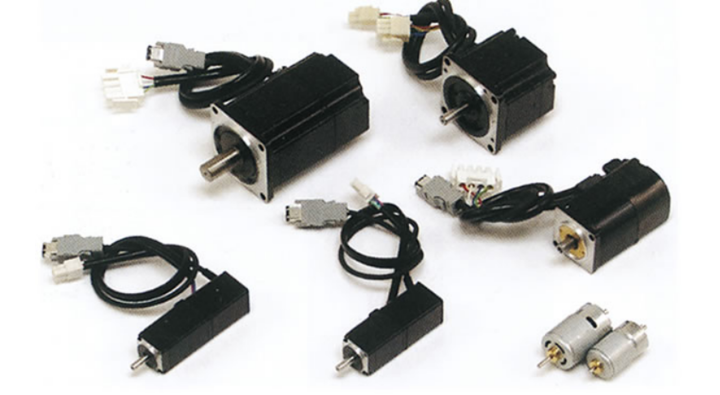

Typical application of hot extrusion radiation-oriented ring three: AC servo motor

Typical application of hot extrusion radiation-oriented ring three: AC servo motor• high efficiency, low inertia, high precision,excellent comprehensive performance of the servo motor, is the foundation of modern industrial automation, actuators, including high-performance electric servo system using permanent magnet synchronous ac servo motor, mostly at home and abroad on behalf of the manufacturer for lanzhou motor, Siemens, mitsubishi, yaskawa, panasonic, FANUC,huazhong CNC, ABB, cole Morgan, etc.

• permanent magnet synchronous ac servo motor is widely used in robot, CNC machining center, film cutting machine, automatic winding machine, vacuum coating machine, automatic welding machine, tobacco machinery, high-speed drilling machine, automatic electronic component inserter in printed circuit board and SMT machine, integrated circuit loading machine and welding machine, automatic packaging machines, printing machines and fiber cable equipment automation, high precision speed, position, torque control and fast frequent operation.

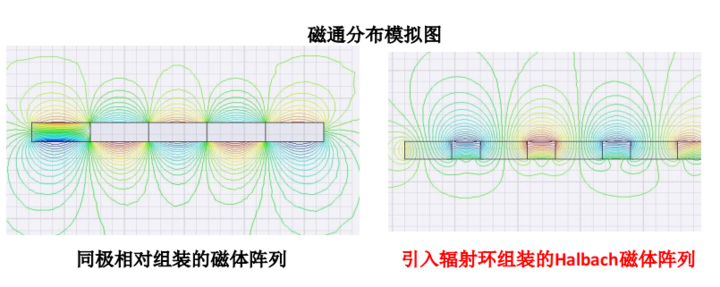

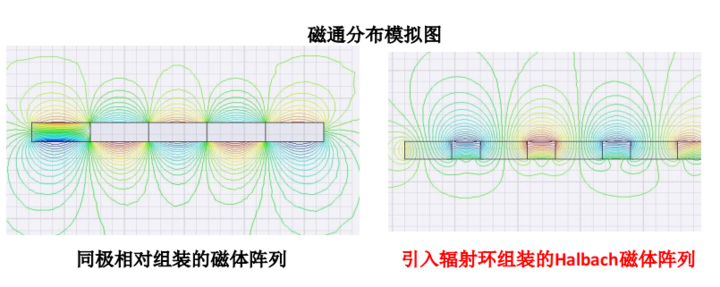

Typical applications of hot extrusion radiation-oriented rings: millibar permanent magnet array

Typical applications of hot extrusion radiation-oriented rings: millibar permanent magnet array•Halbach array arranges the permanent magnets in different magnetization directions in a certain order, so that the magnetic field on one side of the array is significantly enhanced while that on the other side is significantly weakened, and the magnetic field is distributed sinusoidal in space, as shown in Figure 1. These characteristics make Halbach array have a broad application prospect in the field of permanent magnet motor.

•Halbach permanent magnetic array was first proposed by Professor Klaus Halbach of Lawrence Berkeley National Laboratory in the United States, and has been applied in high-energy physics fields such as particle accelerator, free electron laser device and synchrotron radiation device

Scope of business

The main business scope includes the Water treatment,Removal of copper ions; manufacturing and processing of Nd-Fe-B materials, devices, magnetic powder and alloy, permanent magnet motor manufacturing, processing; Magnetic powder for 3D printing (Nd-Fe-B, Mn-Bi), amorphous powder;Surface thermal spraying technology and services, such as wear and corrosion resistant layers .Self-management and agent all kinds of goods and technology import and export business (except country limit or prohibit the import and export of goods and technologies), amorphous soft magnetic materials, molded inductors, Fe-Si-B-C amorphous magnetic powder, etc., Sm-Co, Al-Ni-Co Mn-Bi magnets, magnetic disc and materials, Tb-Dy-Fe, Ni-Mn-Ga magnetostrictive materials, new energy automobile motor, robot servo motor, electric aircraft motor design development and production, such as magnetic chuck magnetic application device research, development, production and sales.ew materials science and technology, electronic technology, mechanical and electrical technology in the field of technology development, technology consulting, technology services, technology transfer, electrical equipment, machinery and equipment manufacturing, processing (limited branch operation) above, electronic processing (limited branch operation), electrical and mechanical equipment and accessories, machinery equipment and accessories, electronic products wholesale, retail, etc.

Contact us

If you have any questions or Suggestions, please feel free to leave a message.

English

恒亿制造. Copyright 2019